metal shearing machine hazards

6 rows DO NOT use this machine unless you have been trained in its safe use and operation. Types of shear or cutting point injuries include amputations lacerations contusions crushing of tissues and bones and broken bones.

Point of Operation Guarding.

. Metal shears may be bench mounted or have integral stands and can be manually powered or electrically hydraulically andor pneumatically powered. Three roll bending machines. Employee Sustains Finger Amputation From Metal Shear.

Determine at least one control strategy from each level of the hierarchy of controls elimination substitution engineering. This instruction applies OSHA-wide. EmployeeS Finger Is Caught In Shear Hold Down And Is Amputa.

Employee Amputates Finger While Feeding Metal Stock Into. Metal shearing machine hierarchy of controls Thursday May 12 2022 The safety guide introduces safeguarding measures that can be retrofitted to your shearing machine. As with any the machine has its fair share of dangers so its important to know about the proper shearing machine safety precautions.

29 CFR 1910212 a 3 ii General Requirements for all Machines. Workers who operate laser cutter and metal shearing machine may face hazards from lifting and carrying manual materials handling. Shear or Cutting Point Safety Precautions.

Moving parts eg risk of injuries from entanglement friction abrasion cutting severing shearing stabbing puncturing impact crushing drawing-in or trapping etc. Potential injuries from shear or cutting point hazards include amputation lacerations contusions crushing of tissue and broken bones. Needs Grading Your organization recently purchased a large metal shearing machine.

Keeping workers safe with machine lockouts. A work-piece is clamped between a punch and a die to create a pre-determined bend. Employee Attempts To Clear Jam In Shear Machine And Receives.

Take necessary safety measures to prevent possible hazards caused by the shearing machineArticle 20 of Act When there is a risk that the stroke end of the machine may endanger workers take safety measures to prevent hazards. These machines can perform a number of functions including shearing punching notching or bending. Clean the Tool Regularly.

These can wear down the tools effectiveness and make it easier to get injured because sheet metal may get caught. Purpose Metal shears are typically used to make straight cuts in flat sheet metal stock. At least once a week if not after each use you should make sure the tool is free of debris.

While this guidance has not been updated to reflect current work health and safety legislation the Health and. These sheet metal brakes are well-known for their versatility ease-of-use minimal maintenance durability and dependability. This will produce cut and create more sheets of various sizes and thicknesses.

For the purpose of this Procedure the term shear will be used to. Due to the speed of mechanical parts injury is inevitable when a body part comes in contact with a shear or cutting point. Awareness Barriers Installed on Metal Cutting Shears.

Determine at least one control strategy from each level of the hierarchy of controls elimination substitution engineering administrative personal protective equipment. This instruction provides guidance for applying awareness barrier safeguards as installed on metal cutting shears. You have been asked to identify the hazards of operating this equipment and make recommendations of ways to control the hazards.

A press brake is one of the popular machines used for sheet metal bending including bottom bending and air bending. Shearing machines work with sharp cutting parts and you can bet that machines that can cut metal can easily cut through skin and bone. Lifting heavy materials during the operation of a laser cutter and metal shearing machine can cause injury to muscles nerves discs and ligaments of the low back.

Article 108-2 of Ordinance Take measures to prevent the body parts of workers from entering the hazardous area. Metal shavings and oil can get caught in your sheet metal shears over time. Shearing or cutting mechanical parts move too fast for you to escape injury once one of your body parts has been exposed to a shear or cutting point hazard.

This video contains the proper safety and operation techniques to correctly use a metal shear. Hazards associated with working near or on machinery vary depending on the exact machine used but can include exposure to.

Brand New Betenbender Hydraulic Shear Sterling Machinery Hydraulic Shear Safety Switch Hydraulic

Safe Operation Of Sheet Metal Guillotine Shear Useful Tips 2022

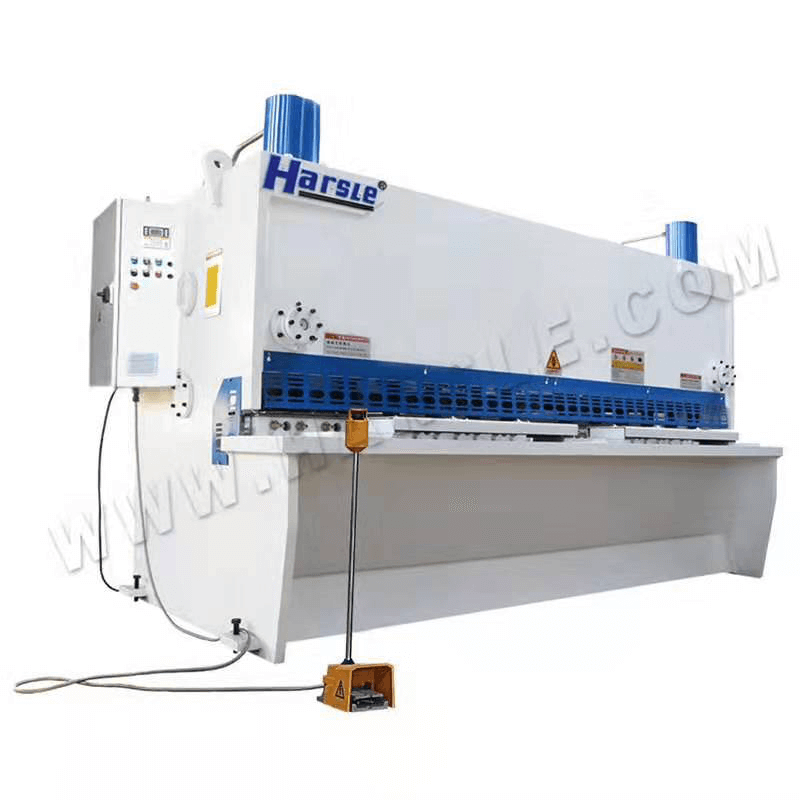

Safe Operation Regulations And Maintenance Of Hydraulic Shearing Machine Harsle Machine

Safe Operation Of Sheet Metal Guillotine Shear Useful Tips 2022

Safety Precautions Tips While Using Sheet Metal Bending Machine Woodward Fab Blog

Unsafe Act During The Bending Process Of Sheet Metal Break Woodward Fab Blog Sheet Metal Metal Bending Sheet Metal Brake

The Precaution Of Sheet Metal Shearing Machine Blma

The Precaution Of Sheet Metal Shearing Machine Blma

How To Increase The Shearing Machine Precision Harsle Machine

![]()

Shear And Punch Machine Safety Procedures Acra Machinery

Punch And Shear Machines Worksafe

Safety Precautions Tips To Follow When Working With Sheet Metal Rolling Equipment Woodward Fab Blog

Safe Operation Of Sheet Metal Guillotine Shear Useful Tips 2022

Get Information On Various Types Of Milling Machines Their Industrial Applications Including The Installation Steps Milling Machine Milling Machines Milling